Chemical Recycling of Plastics Market Volume to Worth 11.90 Million Tons by 2035

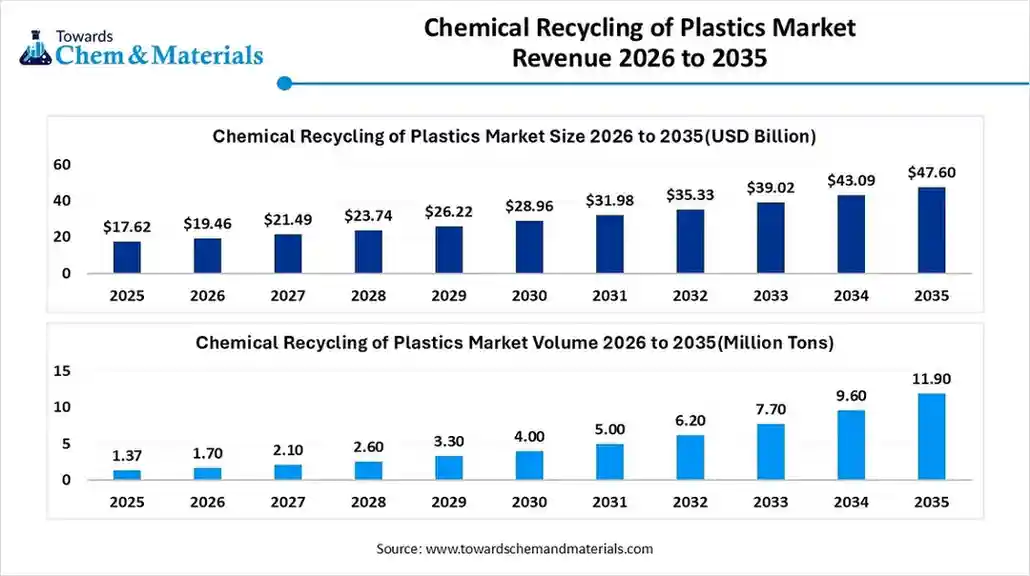

According to Towards Chemical and Materials, the global chemical recycling of plastics market volume was valued at 1.37 million tons in 2025 and is expected to be worth around 11.90 million tons by 2035, exhibiting at a compound annual growth rate (CAGR) of 24.13% over the forecast period from 2026 to 2035.

Ottawa, Jan. 07, 2026 (GLOBE NEWSWIRE) -- The global chemical recycling of plastics market size was estimated at USD 17.62 billion in 2025 and is expected to increase from USD 19.46 billion in 2026 to USD 47.60 billion by 2035, growing at a CAGR of 10.45%. In terms of volume, the market is projected to grow from 1.70 million tons in 2026 to 11.90 million tons by 2035. exhibiting at a compound annual growth rate (CAGR) of 24.13% over the forecast period 2026 to 2035. The Europe dominated Chemical Recycling of Plastics market with the largest volume share of 34% in 2025. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/6118

This market is driven by sustainability for polymers, the circular economy, and increased consumer preference for recycled plastic products due to pollution concerns.

The chemical recycling of plastics refers to processes that are capable of breaking plastic waste down to its original chemical components. Plastic recycling is a complex process that requires attentive sorting to ensure the quality of the recycled material. This process involves depolymerization, pyrolysis, hydro-cracking, and gasification. The closed-loop systems that drive the circular economy of plastics are a key benefit of chemical recycling.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Chemical Recycling of Plastics Market Report Highlights

- By region, Europe led the chemical recycling of plastics market with the largest volume share of over 34% in 2025. The dominance of the region can be attributed to the growing consumer demand for sustainability.

- By region, Asia Pacific is expected to grow at the fastest CAGR over the forecast period. The growth of the region can be credited to the extensive plastic waste generation.

- By region, North America is expected to grow at a notable CAGR over the forecast period. The growth of the region can be driven by the increasing implementation of stringent regulations.

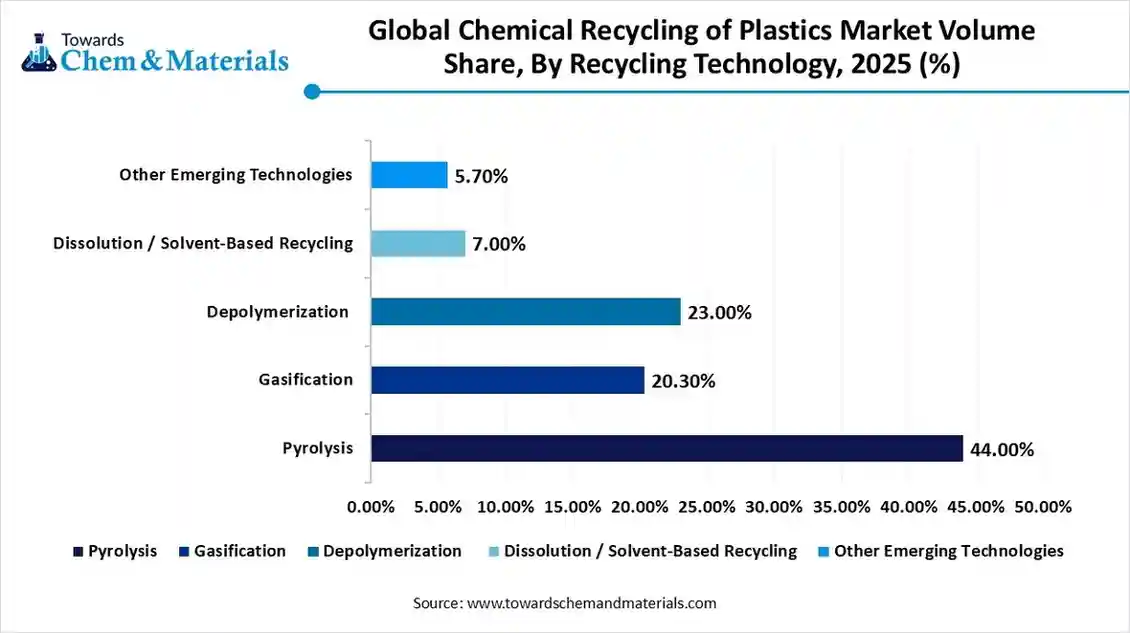

- By recycling technology, the pyrolysis segment dominated the market with nearly 44% volume share in 2025. The dominance of the segment can be attributed to the growing adoption of chemically recycled materials.

- By recycling technology, the depolymerization segment is expected to grow at the fastest CAGR over the forecast period. The growth of the segment can be credited to the rapid technological advancements, which are enhancing efficiency.

- By plastic type, the polyolefins (PE & PP) segment held approximately 58% market volume share in 2025. The dominance of the segment can be linked to the ongoing private and government investments in new recycling facilities.

- By plastic type, the mixed & multilayer plastics segment is expected to grow at the fastest CAGR over the forecast period. The growth of the segment can be driven by growing public concern over plastic waste.

- By end product, the pyrolysis oil segment dominated the market with approximately 46% volume share in 2025. The dominance of the segment is owed to the growing demand for chemical feedstocks.

- By end product, the monomers & chemical feedstocks segment is expected to grow at the fastest CAGR during the projected period. The growth of the segment is due to rapid R&D emphasizing the development of selective catalysts.

- By end-use industry, the packaging segment held nearly 41% market volume share in 2025. The dominance of the segment can be attributed to the government's incentives and investments for advanced recycling technologies.

- By end-use industry, the automotive segment is expected to grow at the fastest CAGR over the study period. The growth of the segment can be credited to the surge in virgin plastic costs and growing consumer demand for green cars.

Key Industrial Investments for Chemical Recycling of Plastics:

- ExxonMobil's $200 Million Expansion: ExxonMobil is investing in expanding its advanced recycling facilities in Baytown and Beaumont, Texas, aiming to process over 500,000 tons of plastic waste annually by 2027 to create certified circular polymers.

- Cyclyx Circularity Center: Cyclyx, in collaboration with ExxonMobil and LyondellBasell, is developing a plastic waste sorting and processing facility near Houston to produce 150,000 metric tons of feedstock per year for both mechanical and chemical recycling.

- Reliance Industries' Pyrolysis Plant: Reliance Industries became the first in India to use a continuous catalytic pyrolysis technology to convert plastic waste into pyrolysis oil, which is then used to produce ISCC-Plus certified circular polymers.

- Eastman Chemical Company's Methanolysis: Eastman is making significant investments in large-scale facilities that use advanced methanolysis to break down complex polyester waste, including colored and multi-layer plastics, into their molecular building blocks for new products.

-

Closed Loop Partners' Circular Plastics Fund: Dow, LyondellBasell, and NOVA Chemicals are initial investors in a catalytic fund aiming to deploy $100 million to improve and increase plastic recycling infrastructure and scalable technologies in the U.S. and Canada.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6118

Chemical Recycling Of Plastics Market Report Scope

| Report Attribute | Details |

| Market Size/ Volume value in 2026 | USD 19.46 Billion / 1.70 Million tons |

| Revenue forecast in 2035 | USD 47.60 Billion / 11.90 Million Tons |

| Growth rate | CAGR of 10.45% from 2026 to 2035 |

| Historical data | 2018 - 2025 |

| Forecast period | 2026 - 2035 |

| Quantitative Units | Volume in Kilotons, Revenue in USD million/billion, and CAGR from 2026 to 2035 |

| Report coverage | Volume forecast, Revenue forecast, competitive landscape, growth factors, and trends |

| Segments covered | By Recycling Technology, By Plastic Type, By End Product, By End-Use Industry, By Region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Country scope | U.S.; Canada; Mexico; Germany; U.K.; France; Italy; Spain; Denmark; Norway; Sweden; China; India; Japan; Brazil; Argentina; Saudi Arabia; South Africa |

| Key companies profiled | Agilyx; BASF SE; MaireTecnimont S.p.A.; INEOS AG; Recycling Technologies; Veolia Environnement SA; JEPLAN, INC.; Eastman Chemical Company; SABIC; LyondellBasell Industries Holdings B.V |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

What Are the Major Trends in the Chemical Recycling of Plastics Market?

- Focus on Sustainability: The policies encouraging market players to implement recycled-content plastics and sustainable solutions. Circular economy and zero waste discharge through advanced recycling, minimizing environmental footprint.

- Growth in Emerging Applications: Beyond packaging, chemical recycled plastics are gaining application in other sectors such as automotive, electrical & electronics, textiles, and construction due to their unique properties and sustainability benefits.

- Advanced Recycling Integration: The technological aspects, like pyrolysis, gasification, and chemical depolymerization, allow unrecyclable plastics to be broken down into original monomers and reused.

- Government Initiatives and collaboration: The government supports and invests in advanced plastics recycling technologies to increase recycling rates. The collaboration between producers, recyclers, consumer brands, and waste management companies is enabling market growth.

The Plastic Solution We Need: How Technological Innovation Is Transforming Chemical Recycling of Plastics

The technological innovation in the chemical recycling of plastic industry transforms waste plastics into their original quality of the recycled material that enhancing circular economy aspects. The advanced pyrolysis and enzymatic recycling is a recent innovation in this market. Artificial intelligence is enhancing plastic recycling by avoiding the waste of key resources and improving accuracy. Pairing AI with spectroscopy will create more sophisticated recycling systems to achieve sorting precision.

Market Opportunity

How is the Integration of the Entire Value Chain Accelerating the Growth of the Plastic Recycling Industry?

The value chain expansion is a pivotal driver in the market, characterized by Integrated collaboration between waste management companies and plastic manufacturers. Value chain integration attracts investment in R&D that fosters innovation to scale up operational efficiency. Additionally, other key aspects are the scope for hard-to-recycle plastics and circular products. The government rules encourage a global sustainable market to lower the environmental impact.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6118

Chemical Recycling of Plastics Market Segmentation Insights

By Recycling Technology

How did the Pyrolysis Segment dominate the Chemical Recycling of Plastics Market in 2025?

The pyrolysis segment is leading the market, driven by its feedstock flexibility and high effectiveness in handling hard-to-recycle plastics. Pyrolysis superheats plastics to break them into monomers, and valuable circular feedstocks such as syngas, naphtha. The increasing focus on reducing environmental impact and strict regulations is driving the adoption of this segment. The companies are investing and using pyrolysis to meet brand commitments to reduce their carbon footprint.

The depolymerization segment is anticipated to grow fastest during the projected period, driven by its high-purity monomer for making virgin-quality plastic and technological advancement. Depolymerization separates polymers like PET back into their basic building blocks, showing ideal application in textiles, carpets, and multilayer packaging. The government supports closed-loop recycling of high-performance polymers, driving the market expansion.

By Plastic Type

Which Plastic Type Segment Held the Dominating Share of the Chemical Recycling of Plastics Market in 2025?

The polyolefins (PE & PP) segment dominated the market, driven by their substantial presence in global waste volumes and extensive use in consumer goods, packaging, bulletproof vests, and automotive components. The polyolefins made from ideal chemical composition by using pyrolysis and gasification have great potential as a source of valuable hydrocarbons. Polyolefins act as versatile end-products that help to achieve a circular economy for plastics.

The mixed & multilayer plastics segment is set to experience the fastest growth. The growth is propelled by logistical efficiency and the need to reduce food waste. The rapid industrialization in various regions is creating a consumer base for these materials. The innovation in advanced chemical recycling methods and companies' initiative for developing mom-materials is accelerating the mixed & multilayer plastics segment.

By End Product

How did the Pyrolysis Oil Segment hold the Largest Share of the Chemical Recycling of Plastics Market?

The pyrolysis oil segment dominated the market because it efficiently handles mixed waste, non-recyclable plastics by converting them into valuable chemical feedstocks or raw material for new plastics. The key focus on circular solutions offers a sustainable alternative to landfilling and a lower carbon footprint by meeting regulatory and consumer demands. The economic viability and energy recovery drive its market leadership.

The monomers & chemical feedstocks segment is anticipated to grow at the fastest CAGR over the forecast period. The market is driven by R&D in catalysts, government support towards circular economies, and feedstock versatility, allowing for the creation of new plastics from waste. The investments in various applications like packaging, automotive, and infrastructure projects are driving this market. This material is used in critical building blocks for polymerization processes in the industrial sector.

By End-Use Industry

Which End-Use Industry Type Segment Leads the Chemical Recycling of Plastics Market in 2025?

The packaging segment led the market, driven by regulatory directives and high consumption of polyolefins and PET. This segment is characterized by e-commerce, strong market demand, and a regulatory push for sustainable solutions. The packaging segment is the largest consumer of plastics and generates large quantities of plastic waste that is used in food, beverage bottles and consumer goods. The demand for green alternatives and consumer awareness is making it the leading end-use segment in this market.

The automotive segment is expected to grow at the fastest CAGR during the estimated period, used in interiors, under-hood components, and bumpers of vehicles. The demand for lightweight materials in vehicles to lower carbon emissions increases the recycled plastics due to their low cost and compatibility. The surge in virgin plastic costs and inclination towards EV battery castings are leading the market expansion.

Regional Insights

How did Europe Dominate the Chemical Recycling of Plastics Market?

The Europe chemical recycling of plastics market was estimated to be USD 5.67 billion in 2025 and is projected to reach USD 15.36 billion by 2035, at a CAGR of 10.48% during the forecast period. By volume, the market is projected to grow from 0.63 million tons in 2026 to 5.39 million tons in 2035. growing at a CAGR of 26.68% from 2026 to 2035.

Europe is dominating the market, driven by stringent government policies and environmental initiatives. The growing investments in chemical recycling technologies, like depolymerization, are improving efficiency and quality, positioning Europe as a global leader in sustainable practices. The EU strategic initiatives, like the EU’s Green Deal, single-use plastics, and public awareness towards pollution, are driving market growth.

Germany Chemical Recycling of Plastics Market Trends:

The Germany’s market is driven by the adoption of manufacturers for sustainable practices, pushing them towards eco-friendly solutions. Germany’s circular economy initiative attracts both producers and recyclers to enhance sorting and processing.

Why is the Asia Pacific the Fastest-Growing Region in the Chemical Recycling of Plastics Market?

The Asia Pacific is the fastest-growing region due to industrialization, growing population, strong government mandates, increasing demand for sustainable solutions, and higher consumption of plastics across multiple markets. The Asia Pacific contains abundant raw material feedstock for recycling, so the volume needing processing, the investment in infrastructure development, and consumer demand for this feedstock drive this regional market.

China Chemical Recycling of Plastics Market Trends:

China's market is the leading country in the Asia-Pacific region due to substantial investments in technological solutions and a robust supply chain ecosystem. The strong government push towards carbon neutrality and domestic demand are pushing this market towards investment and development.

More Insights in Towards Chemical and Materials:

- Biodegradable Plastics Market Size to Reach USD 91.26 Billion by 2034

- Chemical Recycling of Plastics Market Size to Hit USD 47.60 Bn by 2035

- Bioplastics in Diagnostic Devices Market Size to Hit USD 879.46 Million by 2035

- Bioplastics In Medical Devices Market Size to Surpass USD 6.73 Billion by 2035

- U.S. Bioplastics Market Size to Reach USD 21.84 Bn by 2035

- Aerospace Plastics Market Size to Worth Around USD 23.28 Bn by 2035

- Europe Bioplastics and Biopolymers Market Size to Reach USD 34.37 Bn by 2035

- U.S. Bioplastics and Biopolymers Market Size to Surpass USD 34.37 Bn by 2035

- Europe Recycled Plastics Market Size to Surpass USD 33.84 Bn by 2035

- Asia Pacific Recycled Plastics Market Size to Surpass USD 72.11 Bn by 2034

- Recycled Engineering Plastics Market Size to Hit USD 7.89 Billion by 2034

- Mechanical Recycling of Plastics Market Size to Surge USD 92.86 Bn by 2034

- Commodity Plastics Market Size to Hit USD 666.76 Billion by 2034

- U.S. Biodegradable Plastics Market Size to Hit USD 5.27 Billion by 2034

- U.S. Smart Plastics In Precision Agriculture Market Size to Reach USD 1,396.39 Mn by 2034

- U.S. Recycled Plastics in Green Building Materials Market Size and Top Companies Analysis, 2034

- Plastics Market Size to Worth USD 984.11 Billion by 2034

- U.S. Plastics Market Size to Surge USD 131.34 Billion by 2034

- U.S. Recycled Plastics Market Size to Reach USD 131.33 Bn by 2034

- Recycled Plastics Market Size to Surpass USD 190.25 Billion by 2035

- Sustainable Plastics Market Size to Hit USD 1,448.23 Bn by 2034

- Circular Plastics Market Size to Hit USD 182.21 Billion by 2034

- U.S. Transparent Plastics Market Size to Reach USD 35.15 billion by 2034

- Recycled Plastics In Green Building Materials Market Size to Reach USD 12.24 Bn by 2034

- Transparent Plastics Market Size to Hit USD 245.19 Bn by 2034

- Europe Bioplastics Market Volume to Reach 40.16 Million Tons by 2034

- Plastics Extruded Market Size to Surge USD 259.21 Billion by 2034

- Asia Pacific Bioplastics Market Volume to Reach 11.13 Million Tons by 2034

- Bioplastics Market Volume to Reach 73,21,706.6 Tons by 2034

- Engineering Plastics Market Size to Hit USD 312.88 Bn by 2034

- Europe Plastic Market Size to Surpass USD 223.02 Bn by 2034

- Recycled thermoplastics Market Size to Exceed USD 145.34 Bn by 2034

- Thermoplastics In Construction Films Market Size to Hit USD 23.05 Bn by 2034

- High Performance Plastics Market Size to Hit USD 29.36 Bn by 2025

Recent Breakthrough in the Chemical Recycling of the Plastics Industry

- In December 2025, Borealies announced a collaboration with BlueAlp, known for chemical recycling technology leadership, to accelerate the deployment of chemical recycling technologies across Europe. This step boosts innovation and high-quality circular feedstock.

- In February 2025, PolyCycl, which offers a novel solution for recycling, announced the launch of Generation VI chemical recycling pyrolysis technology, enabling the conversion of hard-to-recycle plastics and the formation of a plastic circular economy.

Top Companies in the Chemical Recycling of Plastics Market & Their Offerings:

- Brightmark: Brightmark develops and operates facilities that use plastic waste-to-fuel solutions through a pyrolysis process to create new products like diesel fuel and wax.

- Plastic Energy Ltd: Plastic Energy specializes in converting end-of-life mixed plastic waste into a valuable feedstock, called TACOIL, that can be used to create virgin-quality plastics.

- Agilyx ASA: Agilyx licenses a proprietary advanced recycling technology, primarily focused on depolymerizing polystyrene waste back into its original chemical building blocks for re-use.

- Loop Industries: Loop Industries uses a proprietary depolymerization technology to produce 100% recycled, virgin-quality polyethylene terephthalate (PET) plastic and polyester fiber.

- SABIC: SABIC integrates oil derived from the pyrolysis of mixed plastic waste into its existing petrochemical production processes to produce certified circular polymers.

- BASF SE: BASF's ChemCycling project uses thermochemical processes like pyrolysis and gasification to turn plastic waste into a secondary raw material (pyrolysis oil) which is then used as feedstock in its production Verbund.

- Dow Inc.: Dow is involved in integrating plastic waste-derived feedstocks, often sourced through collaborations like the one with Agilyx and ExxonMobil via the Cyclyx joint venture, into its manufacturing processes to produce circular polymers.

- Eastman Chemical Company: Eastman employs advanced chemical recycling technologies, specifically polyester renewal (methanolysis), to break down hard-to-recycle polyester waste into its molecular building blocks for new products.

- ExxonMobil (Advanced Recycling): ExxonMobil utilizes its proprietary Exxtend™ advanced recycling technology to convert plastic waste into valuable raw materials that are then used to make certified circular polymers on a commercial scale.

- LyondellBasell: LyondellBasell focuses on developing and implementing advanced recycling solutions, including strategic partnerships to secure plastic waste feedstock for producing circular and low carbon solutions.

- Agilyx

- BASF SE

- MaireTecnimont S.p.A.

- INEOS AG

- Recycling Technologies

- Veolia Environnement SA

- JEPLAN, INC.

- Eastman Chemical Company

- SABIC

- LyondellBasell Industries Holdings B.V.

Chemical Recycling of Plastics Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global Chemical Recycling of Plastics Market

By Recycling Technology

- Pyrolysis

- Thermal Pyrolysis

- Catalytic Pyrolysis

- Microwave-Assisted Pyrolysis

- Gasification

- Partial Oxidation Gasification

- Plasma Gasification

- Syngas-to-Chemicals/Fuels

- Depolymerization (Solvolysis-Based)

- Glycolysis

- Methanolysis

- Hydrolysis

- Aminolysis

- Dissolution / Solvent-Based Recycling

- Selective Polymer Dissolution

- Precipitation & Purification

- Other Emerging Technologies

- Enzymatic Recycling

- Catalytic Cracking

By Plastic Type

- Polyolefins

- Polyethylene (HDPE, LDPE, LLDPE)

- Polypropylene (PP)

- Polyesters

- Polyethylene Terephthalate (PET)

- Polybutylene Terephthalate (PBT)

- Styrenics

- Polystyrene (PS)

- ABS

- Engineering & Specialty Plastics

- Polyamides (Nylon)

- Polycarbonates (PC)

- Polyurethanes (PU)

- Mixed & Multilayer Plastics

By End Product

- Monomers & Chemical Feedstocks

- Virgin-Equivalent Polymer Feedstock

- Basic Chemicals (Ethylene, Propylene, Styrene)

- Liquid Fuels & Oils

- Pyrolysis Oil

- Synthetic Diesel/Naphtha

- Gaseous Outputs

- Syngas

- Hydrogen

- Waxes & Specialty Intermediates

By End-Use Industry

- Packaging

- Food & Beverage Packaging

- Consumer & Industrial Packaging

- Automotive

- Interior & Exterior Components

- Building & Construction

- Pipes, Insulation, Profiles

- Electrical & Electronics

- Housings, Components, Wires

- Consumer Goods & Textiles

- Chemical & Refining Industry

- Feedstock Substitution for Virgin Petrochemicals

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6118

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics | TCM Blog

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.